Merino Group brings the warmth and the luxurious charm of natural stone with its new offering — stoven Stone Veneers. Made from real natural stone, the engineering process of combining the strength of fiberglass and thin layers of beautiful natural stone creates hundreds of new possibilities where natural stone can be enjoyed. Stoven is an innovative, eco-friendly, lightweight, flexible product that retains all the natural beauty of the Stone.

| Sr | Code | Design Name | FRP Standard Backing | Engineered Stoven | Cotton Fabric Backing | FRP-Translucent Backing | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1220 X 610 | 2440 X 1220 | 1220 X 610 | 2440 X 1220 | 1220 X 610 | 2440 X 1220 | 1220 X 610 | 2440 X 1220 | |||

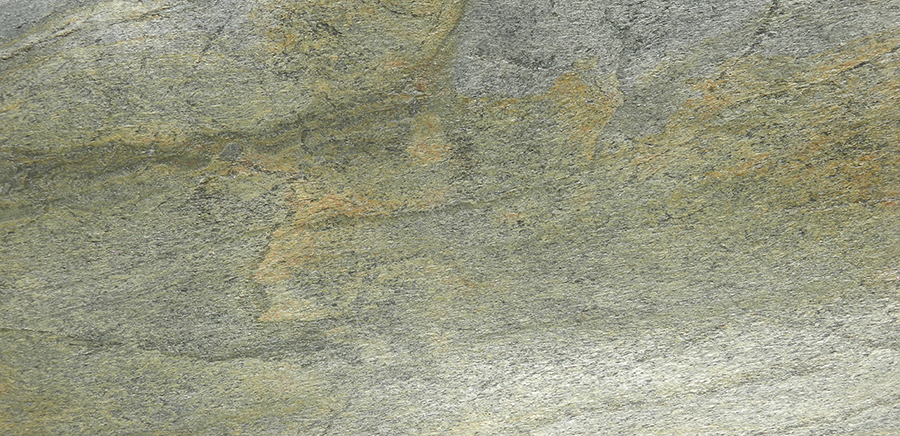

| 1 | 9001 | Aqua Base | Y | Y | Y | Y | N | N | Y | N |

| 2 | 9002 | Balsam Green Slate | Y | N | Y | N | Y | N | Y | N |

| 3 | 9003 | Blanco Slate | Y | Y | Y | Y | N | N | N | N |

| 4 | 9004 | Brick Dust | Y | N | Y | N | Y | N | Y | N |

| 5 | 9005 | Cuban Sand | Y | Y | Y | Y | Y | Y | Y | Y |

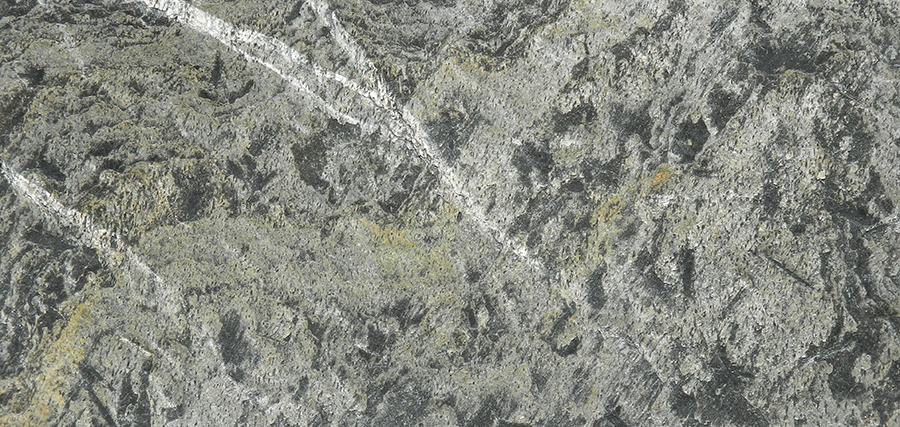

| 6 | 9006 | Dark Spruce | Y | Y | Y | Y | Y | N | Y | Y |

| 7 | 9007 | Earth Crust | Y | Y | Y | Y | Y | Y | Y | Y |

| 8 | 9008 | Fox Slate | Y | Y | Y | Y | Y | N | Y | N |

| 9 | 9009 | Knight Stone | Y | Y | Y | Y | N | N | N | N |

| 10 | 9010 | Lake Stone | Y | Y | Y | Y | Y | N | N | N |

| 11 | 9011 | Magma | Y | Y | Y | Y | N | N | N | N |

| 12 | 9012 | Mantle Crust | Y | Y | Y | Y | Y | Y | Y | Y |

| 13 | 9013 | Peubla Marble | Y | Y | Y | Y | Y | Y | Y | Y |

| 14 | 9014 | Sandstone | Y | Y | Y | Y | Y | N | Y | Y |

| 15 | 9015 | Smoked Pearl | Y | Y | Y | Y | Y | Y | Y | Y |

| 16 | 9016 | Sparkled Granite | Y | Y | Y | Y | Y | Y | Y | N |

SAFETY AND PRECAUTIONS: Precautions should be taken when working with Stoven Slate. ALWAYS wear the right kind of gloves, goggles, and dust masks for protection while the fiberglass backing slates are cut. When cutting, sanding or grinding equipment is used, exhaust ducts should be properly filtered. Avoid breathing silica (quartz composite) and/or fiberglass dust; prolonged exposure to this dust might cause lung cancer or long-term injuries. Work outdoors, in well ventilated areas or use mechanical ventilation. Industry professionals recommends a NIOSH / MSHA approved respirators for this type of material.

| Sr. No | Particulars of Test carried out | Results | Standard Referred to |

|---|---|---|---|

| 1 | Density (at 23+/- 1°c) (gm/cm³) | 1.4 | ASTM D 792-91 |

| 2 | Water absorption in % by weight

· At 23+/- 1°c for 24hrs immersion · Boiling water immersion for 2 hrs |

· 1.3 · 1.5 |

· ASTM D 570-81 · ASTM D 570-81 |

| 3 | Flexural strength (MPa) | 48 | ASTM C 120-90 |

| 4 | SGC Flammability

(Time of ignition – 5sec) |

Sample does not ignite | As per US code of Federal Regulations. Title 16 Part 1500.44 |

| 5 | Thermal Shock Resistance

(After 5 Cycle) |

No visible failure | ASTM C 484-93 |